The production process of jigsaw puzzles can vary depending on the materials used and the complexity of the puzzle design. Here are some general steps that may be involved in the production of jigsaw puzzles:

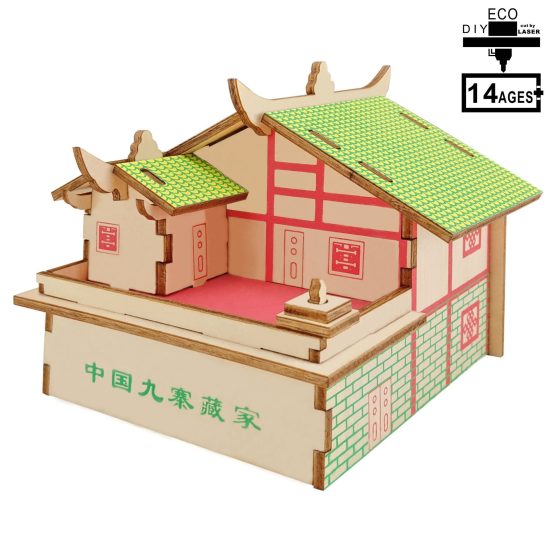

- Design: The first step is to create the puzzle design, which can be done by hand or using computer software.

- Printing: The design is then printed onto the puzzle material, which can be cardboard, wood, or another material.

- Cutting: The puzzle pieces are then cut out from the printed material using specialized cutting machines. The cutting pattern can be a standard grid or a unique, irregular shape.

- Sorting and packaging: The puzzle pieces are sorted into sets and packaged with a reference image for the completed puzzle.

- Quality control: The completed puzzles are inspected for quality, including the accuracy of the printing and cutting, and the overall durability of the puzzle pieces.

- Shipping and distribution: The finished puzzles are then shipped to retailers or directly to customers for sale.

Some manufacturers may also use additional processes such as coating the puzzle pieces for added durability or including special features like glow-in-the-dark or textured pieces. The production process can also vary depending on the scale of the production, with larger manufacturers using more automated machinery and processes.